Lng seals

Subcategories

LNG seals

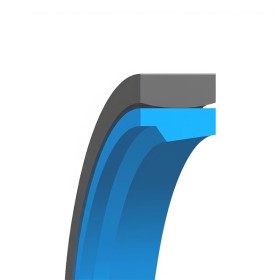

LNG seals are engineered to perform in cryogenic conditions, commonly found in liquefied natural gas storage and transport. Made from PTFE, PCTFE, or cryogenic-grade elastomers, LNG seals maintain flexibility and sealing force at ultra-low temperatures. These seals are widely used in LNG pumps, valves, loading arms, and transfer lines. They resist thermal shock, pressure changes, and aggressive media, ensuring safe and leak-free operation in critical LNG systems.

There is 1 product.

LNG Seals

surfaces and creating a tight barrier to prevent gas or fluids from leaking. The spring also

provides resiliency to compensate for seal wear, gland misalignment, or eccentricity.

While spring force provides adequate force for sealing at low pressure, at high pressure

the system pressure augments the spring force to provide an even tighter seal.