Home

Subcategories

Hydraulic Seals

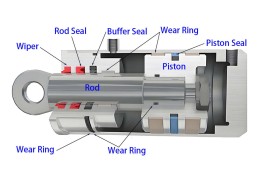

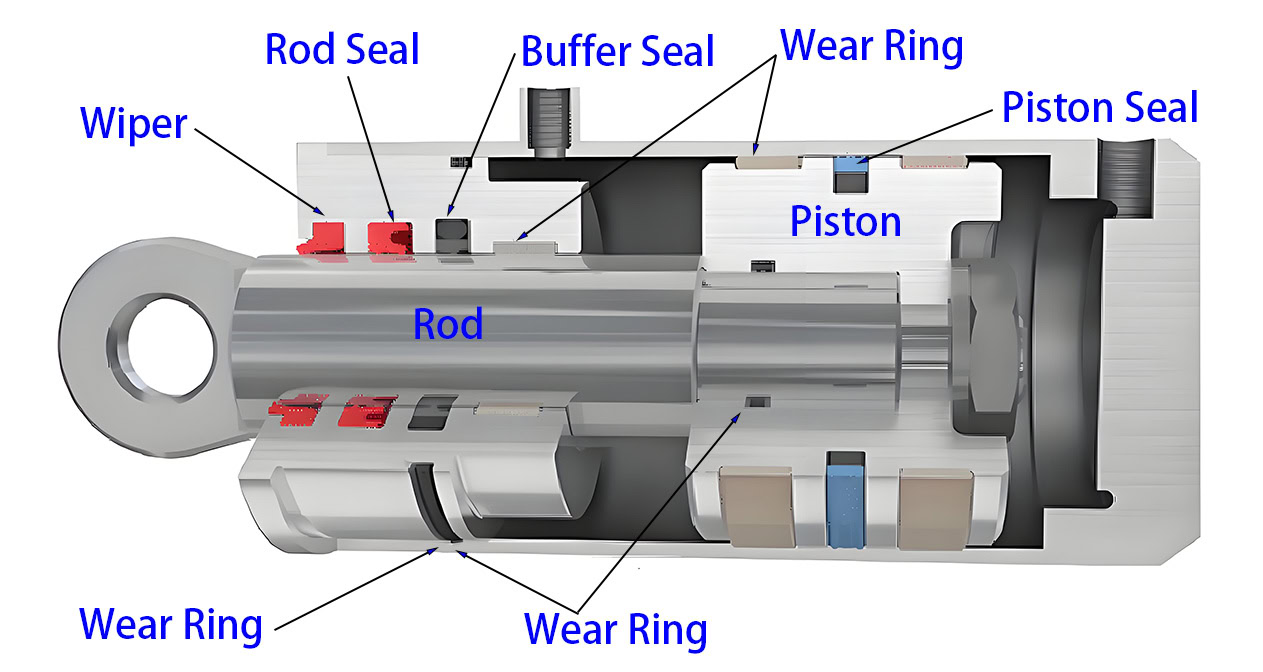

Hydraulic seals are constructed from polyurethane, rubber, or PTFE.Hydraulic seals are widely used in hydraulic cylinders of excavators, bulldozers, cranes, and many other types of heavy equipment.

Dynamic seal and static seal of hydraulic seals Classification. The portfolio covers piston seals, rod seals, seals buffer, and wiper seals along with guide rings and O rings.

Spring Energized Seals

Spring energized seals use a metal spring to apply constant force to the sealing lip, ensuring consistent performance even under variable pressure and temperature. The seal body is typically made from PTFE or other high-performance polymers, offering low friction and chemical resistance. Spring energized seals are ideal for demanding applications such as cryogenics, aerospace, chemical processing, and high-speed rotary systems. Their design allows reliable sealing in dynamic, static, vacuum, and aggressive media environments.

Oil & Gas Seals

Oil & gas seals are designed to perform under high pressure, extreme temperatures, and aggressive media. They prevent leaks in critical systems and ensure equipment reliability. Materials like FKM, HNBR, PTFE, and PEEK are commonly used for their resistance to heat, chemicals, and wear. Oil & gas seals are widely used in downhole tools, valves, pumps, compressors, and subsea equipment. These seals are essential for maintaining safety and sealing integrity in exploration, drilling, and refining operations.

Lng seals

LNG seals are engineered for cryogenic temperatures, often below -160°C, where standard materials fail. These seals are made from PTFE, modified PCTFE, or elastomers specially formulated for low-temperature flexibility and chemical resistance. LNG seals are used in pumps, valves, loading arms, and transfer systems within LNG storage, transport, and processing. They ensure long-term sealing reliability in liquefied natural gas operations, preventing leakage and maintaining system integrity under thermal shock and pressure variations.

There are 63 products.

LNG Seals

surfaces and creating a tight barrier to prevent gas or fluids from leaking. The spring also

provides resiliency to compensate for seal wear, gland misalignment, or eccentricity.

While spring force provides adequate force for sealing at low pressure, at high pressure

the system pressure augments the spring force to provide an even tighter seal.

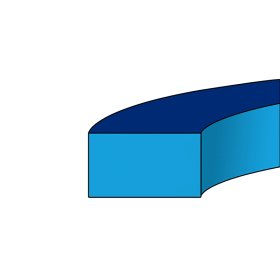

POM Wear Ring

This wear ring is capable of withstanding high side loads and preventing metal-to-metal contact between the piston and the bore or the rod and the gland.

Item NO.: POM

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

Back Up Rings

The back-up rings come standard in Virgin PTFE but can be made from any filled PTFE compound to increase the pressure capabilities.

PEEK,POM, Nylon back up ring are also made.

Item NO.: BUR

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

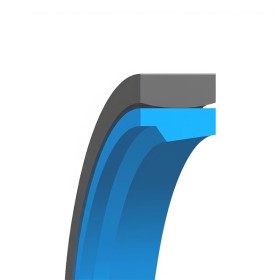

Rod step seal

The Rod step seal is especially suitable for control cylinders, servo systems, machine tools, construction machines, and chemical industry applications.

Different PTFE material sliding rings and rubber material O rings can be selected for different applications to meet different fluid media and temperature ranges.

Phenolic Wear Ring

Spring Packing

Spring Energized Seal (One/Double stack Spring)

Double acting rod seal

The Double Acting Rod Seal, also known as a dual action rod seal, is engineered to deliver bidirectional sealing performance in hydraulic and pneumatic cylinders. It ensures tight sealing during both the extension and retraction strokes, making it an ideal solution for double acting cylinder applications that demand consistent pressure control and zero leakage.

Whether used in high-pressure hydraulic systems or fast-moving pneumatic equipment, this double-lip rod seal provides reliable and durable sealing under dynamic conditions.

PTFE Bronze Wear Ring

O ring

Heavy-Duty Rod Seal

Its ultra-low friction and anti-extrusion properties make it ideal for critical hydraulic applications such as rolling mills, injection molding machines, and hydraulic presses.

View all hydraulic rod seals