Spring Energized Seals

Subcategories

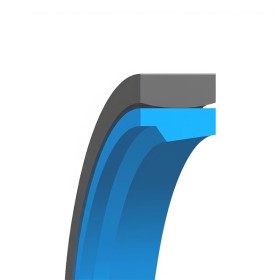

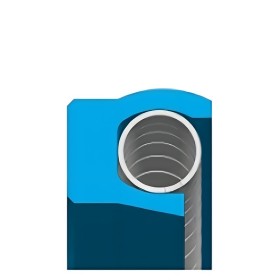

Spring Energized Rod Seals

Spring energized rod seals combine a polymer sealing element with an internal metal spring to provide constant force against the rod surface. This ensures reliable sealing in dynamic applications, especially where pressure, temperature, or media conditions vary. Made from materials like PTFE, PEEK, or other engineered plastics, spring energized rod seals are used in aerospace, chemical processing, cryogenic systems, and high-pressure hydraulics. They offer excellent resistance to wear, extrusion, and chemical attack while maintaining low friction.

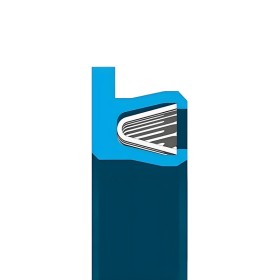

Spring Energized Piston Seals

Spring energized piston seals feature a polymer sealing jacket and an internal spring that applies continuous pressure to maintain contact with the cylinder bore. This ensures tight, low-friction sealing in dynamic conditions. Commonly made from PTFE, PEEK, or other high-performance materials, spring energized piston seals resist wear, chemicals, and extreme temperatures. They are used in aerospace systems, cryogenic equipment, chemical processing, and high-pressure hydraulic cylinders, delivering long-term sealing reliability in demanding environments.

Spring Energized Rotary Seals

Spring energized rotary seals use a metal spring to keep sealing pressure against rotating shafts. They provide consistent sealing even with speed, pressure, or thermal changes. Made from materials like PTFE or PEEK, spring energized rotary seals resist wear, heat, and chemicals. They are used in pumps, compressors, mixers, and rotary joints across industries like aerospace, oil & gas, and chemical processing. These seals offer low friction and long service life in demanding environments.

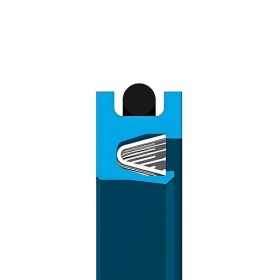

Spring Energized Inside Face Seals

Spring energized inside face seals apply spring force to press the sealing lip against an internal face. This design ensures axial sealing under pressure or vacuum. Made from materials like PTFE or PEEK, spring energized inside face seals resist chemicals, wear, and temperature changes. They are used in valves, static joints, and low-speed rotary systems, especially in aerospace, chemical, and cryogenic applications. These seals offer reliable, low-leakage performance in tight installation spaces.

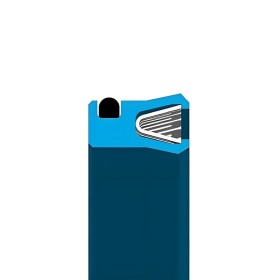

Spring Energized Outside Face Seals

Spring energized outside face seals use a spring-loaded sealing lip to press outward against a housing face. This ensures tight axial sealing under pressure or vacuum. Made from PTFE, PEEK, or other high-performance materials, spring energized outside face seals resist chemicals, wear, and extreme temperatures. They are used in static joints, valve bodies, and flanged connections in aerospace, chemical, and industrial systems. These seals offer long-lasting performance in tight or critical sealing areas.

There are 11 products.

FLANGED CANTILEVER SPRING ENERGIZED SEAL

CANTED COIL SPRING ENERGIZED ROD SEAL

CANTED COIL SPRING ENERGIZED PISTON SEAL

Spring Energized outside face seals

Spring Energized inside face seals

O RING HEEL CANTILEVER SPRING ENERGIZED SEAL

at the bore to counteract rotary forces. With proper hardware design, a high level of sealing can be realized, making an O-Ring Heel Seal a good choice where gaseous or low viscosity fluids need to be sealed.