Discover OEM-equivalent TES Teflon® Seals for Nordson melters. and custom-fit for BM200, VD200, DD200, 5506, 5550,...

FKM vs FFKM: Key Differences, Advantages & Applications

In critical sealing applications across industries such as chemical processing, oil and gas, pharmaceuticals, aerospace, and semiconductor manufacturing, high-performance elastomers are a must. Two of the leading sealing materials in these environments are FKM and FFKM. Although both share common characteristics, they differ in chemical composition, temperature tolerance, chemical resistance, and overall cost. In this article, we will explore the unique characteristics of each material to help you determine which one best suits your application needs.

What are FKM Seals?

FKM seals are made from fluoroelastomers, a type of synthetic rubber that emerged in the 1950s. It is best known under the DuPont brand name Viton®. Characterized by a high content of fluorine, FKM seals offer excellent resistance to oils, chemicals, high temperatures, and aging. These properties make them an ideal choice for many industrial applications where reliable sealing is critical. Examples include situations where NBR cannot be used due to excessive heat and chemical attack.

What are FFKM Seals?

FFKM seals, or perfluoroelastomer seals, take performance a step further by incorporating an even higher fluorine content with the complete absence of carbon-hydrogen bonds. This unique chemical structure endows FFKM with exceptional chemical and heat resistance—qualities that make it indispensable in the most extreme operating conditions. Although FFKM seals come with a higher price tag, they are the top choice for applications where purity and durability are paramount.

Chemical Properties & Composition

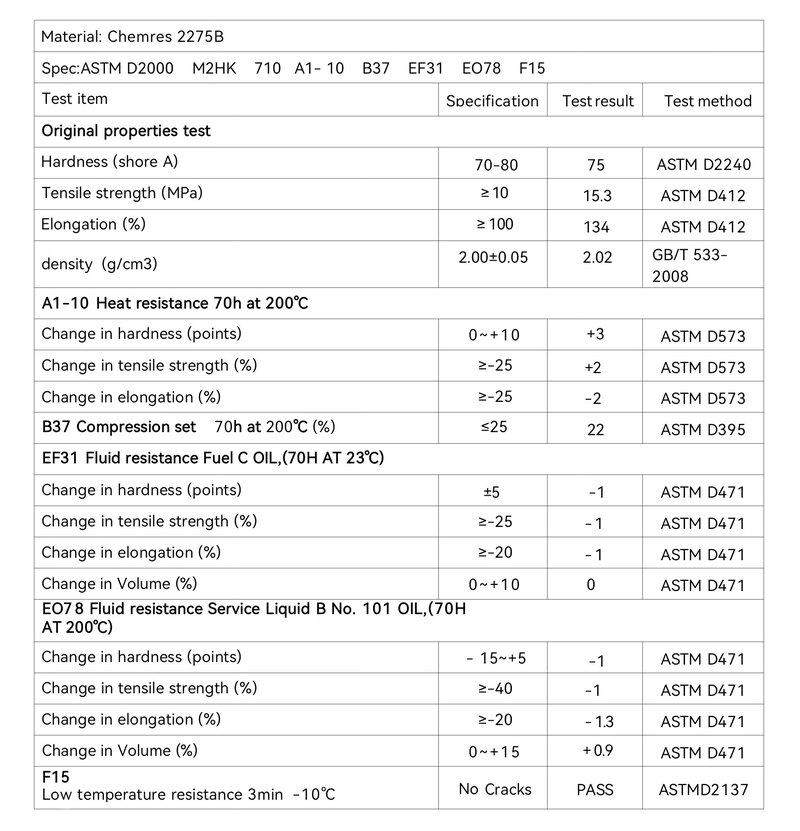

Composition and Properties of FKM

FKM seals are composed of fluorinated polymers that typically include:

Primary Monomers: Vinylidene fluoride, sometimes combined with ethylene and propylene.

Temperature Range: -26°C to +205°/230°C (-15°F to +400°/440°F)

Fluorine Content: Typically ranges between 60% to 70%, providing robust chemical resistance. In general, with increasing fluorine content, resistance to chemical attack is improved, but low-temperature characteristics are diminished, however, specialty grade FKMs are available that can provide high fluorine content with improved low-temperature properties.

| Mechanical, Physical, and Thermal Properties | |

| Hardness shore D(GB/T 531-1999)D | 86±1 |

| Tensile Strength (GB/T 1040-92) (MPa) | 15.3 |

| Elongation(GB/T 1040-92) % | 162 |

| Density(GB/T 533-91) (24°C) | 1.85 |

| Service Temperature Range (℃) | -25/+230 |

| Color | Brown |

Composition and Properties of FFKM

FFKM seals are formulated through a complete fluorination process, which eliminates carbon-hydrogen bonds. Key features include:

Superior Heat Resistance: Operational temperature ranges from -55°C to 350°C.

Enhanced Chemical Resistance: It withstands aggressive chemicals, including strong acids, bases, and organic solvents.

Low Permeability & Contamination: Ideal for processes where contamination must be strictly minimized.

Industrial Applications and Advantages

Advantages of FKM Seals

Versatility: Ideal for a wide range of industrial applications.

Cost-Effectiveness: Provides reliable sealing performance in typical environments at a lower cost.

Applications Include:

Oil and gas processing

Chemical and food processing equipment

Pharmaceutical machinery

Advantages of FFKM Seals

Extreme Environment Adaptability: Excels in high-temperature, high-corrosivity, and low-contamination scenarios.

Enhanced Reliability: Favored in critical applications where failure is not an option.

Applications Include:

Semiconductor manufacturing equipment

Aerospace and defense systems

High-end chemical processing equipment

Cost & Market Considerations

Although FFKM seals outperform FKM in extreme conditions, their high manufacturing costs and the complexity of raw materials result in a significantly higher price point. When choosing a seal, companies must consider the following:

Raw Material Costs: FFKM uses premium ingredients that impact overall pricing.

Production Complexity: More advanced curing and processing techniques are required.

Supply Chain Stability: FFKM seals might have longer lead times due to the limited number of suppliers.

For many applications, FKM remains a reliable and economically viable choice, delivering excellent performance where extreme resistance is not mandatory.

Choosing Between FKM and FFKM

When deciding which seal type to use, consider the following factors:

Operating Conditions:

For environments exceeding 260°C or requiring resistance to highly corrosive chemicals, FFKM is the optimal choice.

For most industrial settings, FKM offers sufficient performance.

Budget:

FKM seals are more cost-effective for general applications.

For mission-critical components or harsh environments, the investment in FFKM seals can significantly reduce downtime and maintenance costs.

Supply Chain and Lead Time:

In situations where supply is uncertain, FKM may serve as an effective interim solution.

Conclusion

In the realm of high-performance seals, both FKM and FFKM have their merits. FKM seals offer excellent performance for a broad range of industrial applications, whereas FFKM seals deliver unparalleled resistance in extreme environments. The decision ultimately depends on the specific working conditions, cost considerations, and desired reliability. With the right choice, companies can ensure uninterrupted and efficient operations.

Why Choose XHH Seals?

At XHH Seals, we bring 15 years of industry experience and advanced manufacturing expertise to every project. Our commitment to quality and innovation ensures that you receive customized sealing solutions designed to meet your precise needs. Here’s what sets us apart:

Exceptional Product Quality: Engineered to provide long-lasting reliability and performance.

Customized Solutions: Tailored sealing technologies designed for your unique challenges.

Responsive Technical Support: Our team is ready to assist with all your sealing requirements.

Efficient Production: Robust manufacturing capabilities guarantee timely delivery.

For further inquiries or a custom quote, please contact us at:

Email: xhh@xhh-smartech.com

Leave a comment