Discover OEM-equivalent TES Teflon® Seals for Nordson melters. and custom-fit for BM200, VD200, DD200, 5506, 5550,...

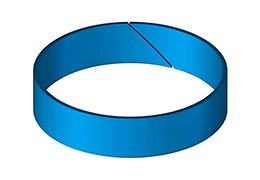

Understanding Wear Rings: Essential Components in Hydraulic Systems

What Are Wear Rings?

In hydraulic and pneumatic systems, wear rings—also known as guide rings or wear bands—play a pivotal role. They prevent metal-to-metal contact, absorb side loads, and protect seals and cylinders from damage, thereby extending the overall system's lifespan.

Primary Functions of Wear Rings

- Prevent Metal Contact: Acts as a barrier between the piston and cylinder, reducing friction and thermal damage.

- Absorb Side Loads: Effectively handle lateral forces during operation, maintaining system stability.

- Extend Seal Life: Minimize wear on seals, reducing leakage risks and enhancing reliability.

Common Materials Used for Wear Rings

Wear rings are manufactured from various materials to suit different operational conditions:

- Glass Fiber Reinforced Nylon: Offers excellent mechanical strength and wear resistance, ideal for high-load environments.

- Bronze-Filled PTFE: Combines low friction with good thermal conductivity, suitable for high-speed systems.

- Phenolic Resin: Provides good heat resistance and mechanical properties, suitable for high-temperature environments.

- Carbon Fiber Reinforced Composites: Lightweight and high-strength, suitable for weight-sensitive applications.

Applications of Wear Rings

Wear rings are widely used in:

- Construction Machinery: Hydraulic cylinders in excavators, loaders, and other heavy equipment.

- Industrial Automation Equipment: Injection molding machines, die-casting machines, and other precision-controlled equipment.

- Aerospace: Hydraulic systems in aircraft landing gear and control systems.

- Automotive Industry: Hydraulic cylinders in steering and braking systems.

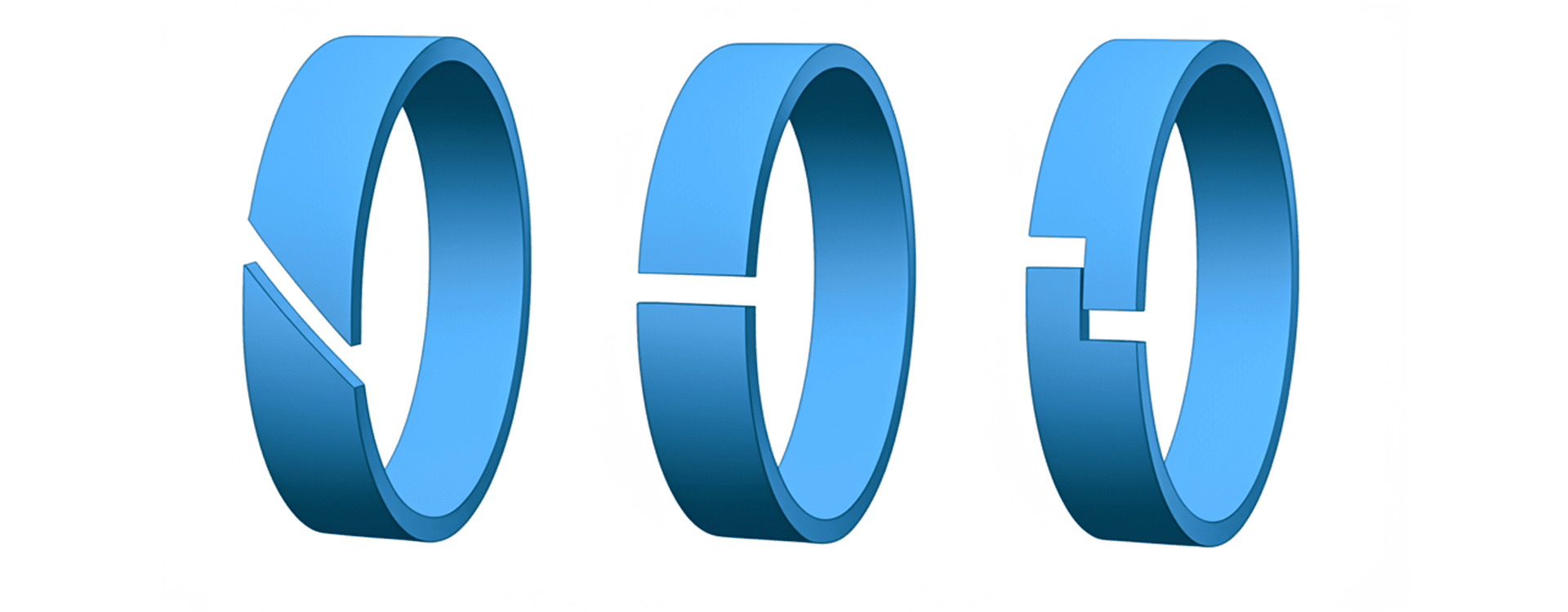

How to Selecting the Right Wear Ring

Consider the following factors when choosing a wear ring:

- Operating Temperature and Pressure: Ensure the material can withstand expected conditions.

- Motion Speed: High speeds may require materials with low friction coefficients.

- Media Compatibility: Consider compatibility with the system's fluids or gases.

- Installation Space: Select appropriate dimensions and shapes based on equipment structure.

Conclusion

Though small, wear rings are crucial in hydraulic systems. Choosing the right material and design enhances system performance, extends equipment life, and reduces maintenance costs.

For more information on wear rings or to obtain customized solutions, please write to: xhh@xhh-smartech.com.

Leave a comment