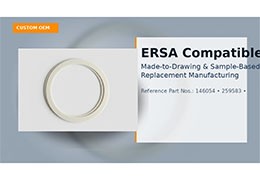

Need ERSA® seal replacements? Send a drawing or sample and XHH Seals can manufacture compatible parts for reference...

-

Replacement Parts Compatible with ERSA® Seals | Made by Drawing or SampleRead more

Replacement Parts Compatible with ERSA® Seals | Made by Drawing or SampleRead more -

Replacement 7288777 Spring Poppet for Nordson® AsymtekRead more

Replacement 7288777 Spring Poppet for Nordson® AsymtekRead moreCompatible replacement spring poppet for Nordson® Asymtek® equipment. OEM reference: 7288777 (for identification...

-

Replacement PTFE Diaphragms for Shimadzu® LC PumpsRead more

Replacement PTFE Diaphragms for Shimadzu® LC PumpsRead moreCost-effective aftermarket PTFE diaphragms manufactured by XHH Seals. Matches Part Numbers: 228-55272-41 &...

-

Pneumatic PTFE Piston Cup Seals for Nordson®-Type Dispensing PumpsRead more

Pneumatic PTFE Piston Cup Seals for Nordson®-Type Dispensing PumpsRead morePTFE and PTFE-composite pneumatic piston cup seals for Nordson®-type dispensing pumps and jet valves. Stable...

-

Cryogenic Seals for LNG and Industrial Gas SystemsRead more

Cryogenic Seals for LNG and Industrial Gas SystemsRead moreEngineer’s guide to cryogenic seals for LNG valves, nozzles and pumps. Learn key designs, materials and how to...

-

AMAT 3700-01485 Compatible Large Dynamic Radial Seal | XHH Engineered SolutionsRead more

AMAT 3700-01485 Compatible Large Dynamic Radial Seal | XHH Engineered SolutionsRead moreCompatible replacement for AMAT 3700-01485 large dynamic radial seal. Sample-based reverse engineering, CNC machining...

-

AMAT 3700-01484 Compatible Dynamic Radial SealRead more

AMAT 3700-01484 Compatible Dynamic Radial SealRead moreLooking for AMAT 3700-01484 replacement? XHH Seals manufactures compatible dynamic radial seals (1.241 OD x 0.998 ID)...

-

AR10414-113-WC Compatible Rod Spring Energized Rotary Lip SealRead more

AR10414-113-WC Compatible Rod Spring Energized Rotary Lip SealRead moreXHH Seals manufactures compatible replacements for AR10414-113-WC rod spring energized rotary lip seals (PTFE+PHB,...

-

High-Performance Replacement Seal Kits for Nordson® Hot Melt SystemsRead more

High-Performance Replacement Seal Kits for Nordson® Hot Melt SystemsRead moreXHH Seals supplies OEM-equivalent and custom replacement seal kits for Nordson® hot melt systems — ProBlue®, UM22,...

-

Nordson Compatible Seals and Spare Parts CatalogRead more

Nordson Compatible Seals and Spare Parts CatalogRead moreDiscover high-quality replacement seals, O-rings, and shaft seals compatible with Nordson hot melt, powder coating,...

-

Top 5 Seal Failures in Nordson® Systems and How to Prevent ThemRead more

Top 5 Seal Failures in Nordson® Systems and How to Prevent ThemRead moreDiscover the top 5 seal failures in Nordson® ProBlue and hot melt systems. Learn expert tips to prevent leaks, reduce...

-

TES Teflon® Encapsulated Seals – OEM Replacement Plates & Rings for Nordson-Compatible MeltersRead more

TES Teflon® Encapsulated Seals – OEM Replacement Plates & Rings for Nordson-Compatible MeltersRead moreDiscover OEM-equivalent TES Teflon® Seals for Nordson melters. and custom-fit for BM200, VD200, DD200, 5506, 5550,...