LNG Fueling Nozzle Spring Energized Seal Kit – Compatible with 50GPM Nozzles (Model 50E701)

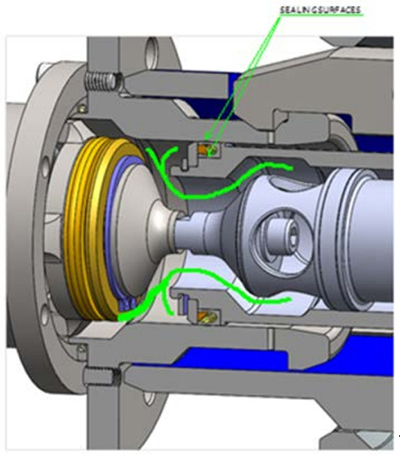

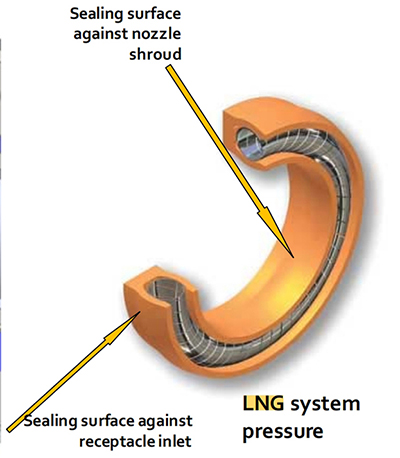

Our LNG Fueling Nozzle Spring Energized Seal Kit is compatible with 50GPM fueling nozzles (Model 50E701 -1, -2, -3) commonly used in LNG fueling systems. These seals are engineered for use in cryogenic environments, offering a spring-energized design that ensures a tight, leak-free seal under extreme low temperatures and high-pressure conditions.

Key Features:

Spring Energized Design: Provides a reliable seal under fluctuating pressures and temperatures, ideal for LNG fueling systems.

Cryogenic-Grade Materials: Built to withstand the extreme cold temperatures and high-pressure conditions typical of LNG applications.

Leak-Free Performance: Guarantees optimal sealing and prevents leakage in LNG fueling, storage, and transfer systems.

Compatibility with 50GPM Nozzles (Model 50E701 -1, -2, -3): Perfectly fits 50GPM nozzles, ensuring a seamless replacement solution.

Whether you're maintaining an LNG fueling station, managing storage tanks, or handling LNG transfer pipelines, this spring energized seal kit ensures your systems operate safely and efficiently, without risk of leakage.

Spring Energized Seal Installation/Replacement

Installation Components:

• Kit, Seal Replacement (P/N B91548-1) content:

Seal, Spring Energized -P/N B78705-6

Retainer Seal -P/N B84398-1

Ring Retainer -P/N 93223-112

• Tools required:

Retaining Ring Pliers

Installation/Replacement

• Push the nozzle handles all the way up and put

nozzle on a flat surface with nose piece facing up.

• Remove Retaining ring (B91877SS-112) using Retaining Ring Pliers

• Remove Brass Seal Retainer (B84398-1)

Remove used Spring Energized Seal (B78705-6)

• Carefully install new Spring Energized Seal (B78705-6)

Note: Pay attention to direction of seal opening; it must be face up.

• Reverse order to reassemble.

References:

JC Carter Official Website. "50 GPM Nozzles." Accessed April 2025. https://jccarternozzles.com/

feedback Report comment