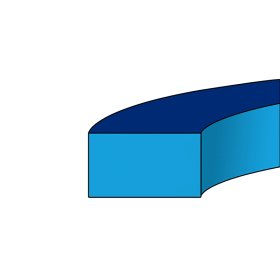

CANTILEVER SPRING ENERGIZED PISTON SEAL

Cantilever Spring Seals make use of a V shaped spring embedded in a polymer jacket. At installation, the V shape of the spring is compressed, providing sealing energy to the seal jacket ensuring a positive seal. They are common replacements when rubber u-cups fail due to chemical attack, extreme temperature range, friction concerns and wear issues. Cantilever Spring Seals are best suited for reciprocating applications such as shocks, hydraulic cylinders, pumps and compressors. The shape of the spring concentrates load on the front of the seal, which makes this design also suitable for use as environmental excluders and for applications requiring scraping of viscous media. As an additional option, the spring cavity area can be filled with silicone for FDA clean-in-place applications.

STANDARD SEAL MATERIALS | |||||||||||||||

|

STANDARD SPRING MATERIALS

Spring Material | Application |

300 Series Stainless Steel | General purpose, standard spring material |

Elgiloy | Improved performance and corrosion resistance |

Hastelloy C276 | Maximum chemical/corrosion resistance |

feedback Report comment