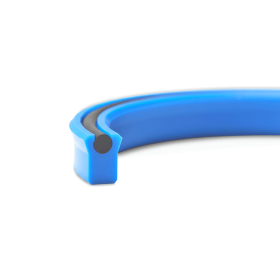

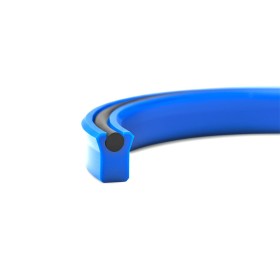

Double acting rod seal

Product Overview

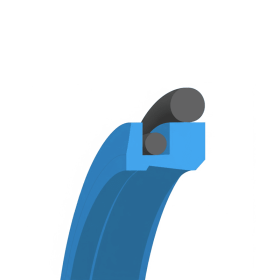

The Double Acting Rod Seal, also known as a dual action rod seal, is engineered to deliver bidirectional sealing performance in hydraulic and pneumatic cylinders. It ensures tight sealing during both the extension and retraction strokes, making it an ideal solution for double acting cylinder applications that demand consistent pressure control and zero leakage.

Whether used in high-pressure hydraulic systems or fast-moving pneumatic equipment, this double-lip rod seal provides reliable and durable sealing under dynamic conditions.

Key Features

- Dual-lip design for maximum sealing efficiency in both directions

- Excellent resistance to extrusion, wear, and high-pressure spikes

- Compatible with a wide range of hydraulic cylinder rod diameters

- Designed for long service life in dynamic applications

- Supports both standard and custom rod seal sizes

- Easy to install and maintain

Ideal for replacing worn hydraulic rod seals in double-acting piston systems

Material Options

We offer several premium-grade sealing materials for different operating environments:

| Material | Properties |

| PU | High elasticity, excellent abrasion resistance, ideal for double acting hydraulic seals |

| PTFE | Low friction, high chemical and temperature resistance, great for high-speed sealing |

| NBR | Excellent oil resistance, suitable for most hydraulic fluids |

| FKM | Outstanding heat resistance and chemical durability |

Looking for custom material rod seals? We offer personalized compound development for your application needs.

Manufacturing Process

- XHH Seals, as a trusted rod seal manufacturer in China, ensure every product meets international quality standards:

- Raw Material Selection – We source high-quality polymers and elastomers.

- Precision Mold Engineering – Tailored for both standard and OEM rod seal sizes

- CNC Machining – Tight tolerance control up to ±0.01mm.

- 100% Inspection – Inspect all seals to ensure they are of the required quality.

- Packaging – Usually all seals are packed with plastic bags, but we can also use other packaging if needed.

Available Sizes

Contact us for standard sizes or custom sizing.

Applications

- Our double acting seals are used across multiple industries and machinery types:

- Hydraulic and pneumatic cylinders

- Double acting piston systems in construction and mining equipment

- Agricultural machinery (tractors, loaders)

- Offshore and marine hydraulics

- Steel mills and heavy industrial equipment

Perfect for systems requiring dual action hydraulic sealing under extreme load and temperature.

Why Choose XHH Seals?

- Professional hydraulic rod seal manufacturer in China with 15+ years of experience

- Provide OEM and ODM support to global customers, customized sealing solutions

- In-house design, mold making, and quality control

- Strict quality control with 99.5% pass rate

- Fast lead time and responsive service team

- Exported to 60+ countries worldwide

Cooperation Process

We streamline international cooperation for fast and efficient delivery:

- Send Inquiry – Share your requirements, size, material, and quantity

- Receive Quotation – Response within 24 hours

- Sample / Order Confirmation – Samples for quality approval

- Production – 7–15 working days, depending on quantity

- Shipping – Global delivery by express, air, or sea

- After-sales – Lifetime support for technical and quality issues

Frequently Asked Questions

Q1: What's the difference between a double acting and single acting rod seal?

A: A double acting rod seal provides sealing in both directions, while a single acting seal works in only one direction of rod movement.

Q2: Can I get customized double acting piston rod seals?

A: Yes, we offer fully customizable sizes, profiles, and materials based on your working environment.

Q3: Do you support small batch or sample orders?

A: Absolutely! Usually, it will take 3-7 days.

Q4: Are you a manufacturer or trading company?

A: We are a direct manufacturer based in China with full control over production and quality.

feedback Report comment