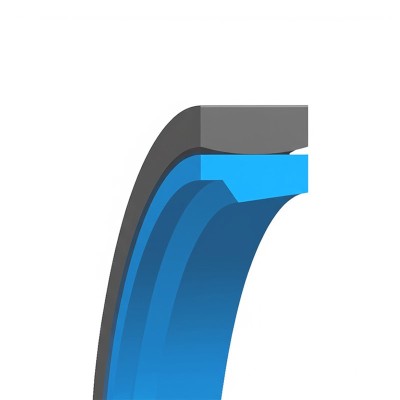

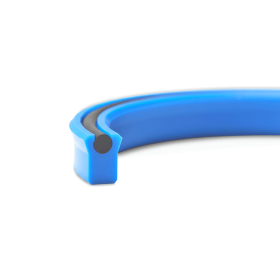

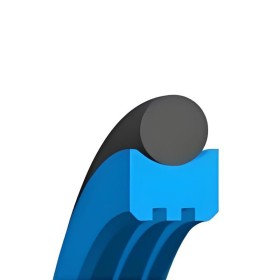

Heavy-Duty Rod Seal

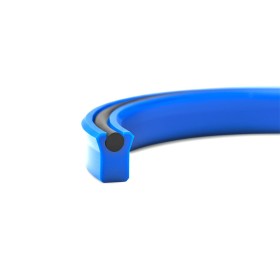

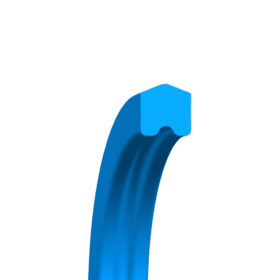

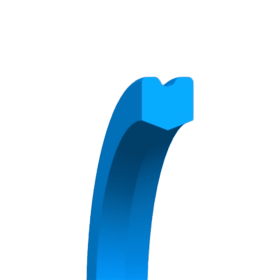

This heavy-duty hydraulic rod seal is engineered for high-performance sealing in large-diameter, high-pressure environments. Featuring a PTFE-filled sealing element and a profiled energizer, it ensures reliable performance in systems with wide extrusion gaps, short strokes, and oscillating motion (dithering).

Its ultra-low friction and anti-extrusion properties make it ideal for critical hydraulic applications such as rolling mills, injection molding machines, and hydraulic presses.

Key Benefits

Ultra-low friction for reduced energy loss

Excellent wear resistance for extended service life

Reliable sealing under short-stroke or dither motion

Withstands high pressures up to 400 bar (6,000 psi)

Broad chemical compatibility with hydraulic and synthetic fluids

Available in diameters up to 1600 mm

Easy to install; no twisting during installation

Material Selection Guide

| Material Code | PTFE Compound | Energizer | Key Properties |

|---|---|---|---|

| MT23 | PTFE + Bronze | NBR | General-purpose, low friction |

| MT26 | PTFE + Bronze | FPM | Higher temp resistance, chemical stability |

| MT83 | PTFE + Glass + MoS₂ | NBR | Enhanced wear resistance |

| MT86 | PTFE + Glass + MoS₂ | FPM | Best for high temp and aggressive fluids |

Custom compounds are available upon request.

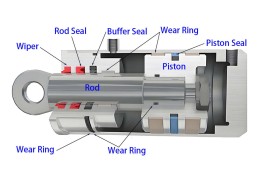

Applications

This heavy-duty rod seal is ideal for:

Rolling mills

Injection molding machines

Hydraulic presses

Forging presses

Large-bore hydraulic cylinders

Short-stroke or oscillating systems

Design & Installation Notes

Designed for wide extrusion gaps and large rod diameters

Compatible with both metric and inch series

Surface finish and tolerances should meet ISO seal housing standards for optimal performance

feedback Report comment