LNG Seals

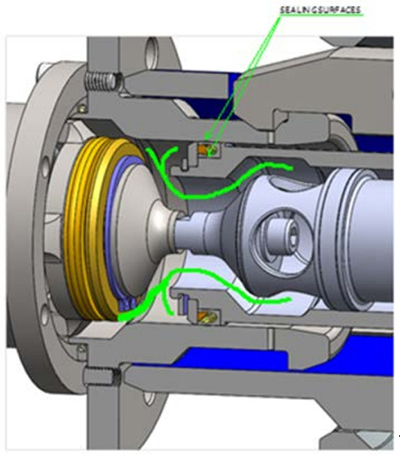

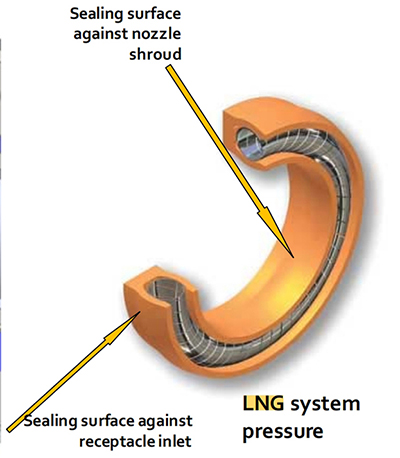

When the LNG seal is seated in the gland, the spring is under compression, applying force on the gland sealing

surfaces and creating a tight barrier to prevent gas or fluids from leaking. The spring also

provides resiliency to compensate for seal wear, gland misalignment, or eccentricity.

While spring force provides adequate force for sealing at low pressure, at high pressure

the system pressure augments the spring force to provide an even tighter seal.

Spring Energized Seal :(P/N B78705-6)

Possible Causes Of Reduction in LNG Seal Performance:

- Ice buildup in the spring coils.

- Abrasive dirt deposits on the sealing surfaces.

- Ice buildup on the sealing surfaces.

- Sharp edges on the vent holes in the receptacle can damage the sealing surface.

Preventive Actions To Increase LNG Seal Life:

- Clean the seal with dry compressed air or nitrogen before and after every use.

- Do not insert the nozzle into the receptacle if ice accumulates on internal receptacle surfaces or the nozzle outlet area.

- Defrost ice with dry compressed air or nitrogen.

- If heated dry compressed air is accessible, it will reduce the defrosting time.

- Check the inlet of the receptacle before engaging the nozzle. If dirt is noted, wipe it clean with a soft, lint-free cloth.

feedback Report comment